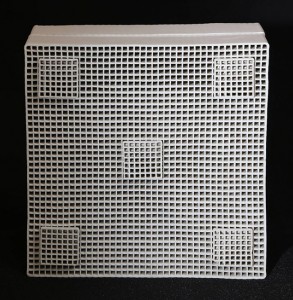

Segmented Honeycomb for Regenerative Thermal Oxidizers (RTOs)

Improved drop-in replacement with enhanced performance and reliability

Lantec's Segmented Honeycomb™ is an improved drop-in replacement for traditional honeycomb monolith, delivering the same proven performance with enhanced plugging resistance and thermal shock protection in regenerative thermal oxidizers.

Segmented Honeycomb provides the same fundamental heat transfer geometry as traditional honeycomb while addressing key operational challenges through intelligent design optimization. While conventional monolithic honeycomb can experience particle buildup in long channels and thermal stress concentration, Lantec's segmented design eliminates these issues by creating shorter flow paths and turbulent mixing zones between segments, reducing the risk of channel plugging.

The segmented design also provides improved thermal shock resistance compared to monolithic structures. Heat transfer performance remains equivalent to conventional honeycomb, with the same pressure drop characteristics and thermal efficiency.

The segmented architecture enables more economical manufacturing compared to traditional monolith extrusion, reducing production costs while maintaining the same high-quality ceramic performance.

Key Benefits

-

Drop-in Replacement – Equivalent heat transfer efficiency and pressure drop characteristics as traditional honeycomb monolith

-

Enhanced Plugging Resistance – Segmented design prevents particle buildup in long channels through natural mixing zones

-

Superior Thermal Shock Protection – Distributed thermal zones reduce stress concentration during temperature cycling

-

Significant Cost Savings – Manufacturing innovation enables more competitive pricing than traditional honeycomb without performance compromise

-

Standard Configurations – Available in all conventional cell densities (25, 30, 40, 43, 50, 60, etc.) to match existing specifications

Performance Data & Literature

Case Studies

Technical Specifications

Segmented Honeycomb Physical Properties – British Units

| Media Type | SHC-25 | SHC-40 | SHC-43 | SHC-50 |

|---|---|---|---|---|

| Cell Count | 25 x 25 | 40 x 40 | 43 x 43 | 50 x 50 |

| Module Size (in x in x in) | 5.9 x 5.9 x 3.0 / 5.9 x 5.9 x 5.9 | 5.9 x 5.9 x 3.0 / 5.9 x 5.9 x 5.9 | 5.9 x 5.9 x 3.0 / 5.9 x 5.9 x 5.9 | 5.9 x 5.9 x 3.0 / 5.9 x 5.9 x 5.9 |

| Heat Capacity (BTU/ft³-°F) | 10.0 | 10.9 | 10.9 | 11.3 |

| Weight (lb/ft³) | 41 | 44 | 44 | 46 |

| Void Fraction (%) | 72 | 70 | 70 | 68 |

| Specific gravity of ceramic | 2.2 – 2.5 | 2.2 – 2.5 | 2.2 – 2.5 | 2.2 – 2.5 |

| Water absorption (ASTM C373) | ≤ 3.0 % | ≤ 3.0 % | ≤ 3.0 % | ≤ 3.0 % |

| Maximum working temp | 2,025 °F | 2,025 °F | 2,025 °F | 2,025 °F |

Segmented Honeycomb Physical Properties – Metric Units

| Media Type | SHC-25 | SHC-40 | SHC-43 | SHC-50 |

|---|---|---|---|---|

| Cell Count | 25 x 25 | 40 x 40 | 43 x 43 | 50 x 50 |

| Module Size (mm x mm x mm) | 150 x 150 x 75 / 150 x 150 x 150 | 150 x 150 x 75 / 150 x 150 x 150 | 150 x 150 x 75 / 150 x 150 x 150 | 150 x 150 x 75 / 150 x 150 x 150 |

| Heat Capacity (kJ/m³ °K) | 674 | 728 | 728 | 760 |

| Weight (kg/m³) | 660 | 710 | 710 | 740 |

| Void Fraction (%) | 72 | 70 | 70 | 68 |

| Specific Gravity of Ceramic | 2.2 – 2.5 | 2.2 – 2.5 | 2.2 – 2.5 | 2.2 – 2.5 |

| Water Absorption (ASTM C373) | ≤ 3.0 % | ≤ 3.0 % | ≤ 3.0 % | ≤ 3.0 % |

| Maximum working temp | 1110°C | 1110°C | 1110°C | 1110°C |

Resources

Downloads

-

{{DOWNLOADS_LIST}}

Related Products

-

{{RELATED_PRODUCTS_LIST}}