Q-PAC®: The Art of Engineering

Revolutionary Drip Point Technology

Q-PAC's patented drip point technology delivers superior mass transfer efficiency with remarkably low pressure drop. This high-capacity packing enables smaller tower diameters, reduced equipment sizes, and significant cost savings for new installations. Its proven fouling resistance makes Q-PAC ideal for scrubber retrofits and challenging tower packing applications.

A Major Advance in Packed Tower Technology

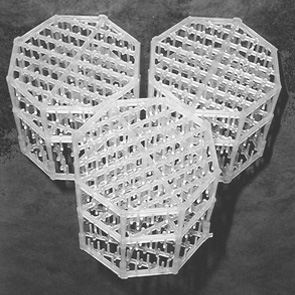

High-capacity Q-PAC creates exciting new possibilities in packed tower design. Q-PAC's patented structure uses drip points and gas turbulence to create millions of small droplets, multiplying the surface area for gas-liquid contact with minimal resistance to gas flow.

Revolutionary Drip Point Technology

Traditional packings like saddles or Pall Rings spread liquid over extended plastic surfaces—a two-dimensional design where the liquid film facing the packing itself doesn't participate in mass transfer. Q-PAC works differently.

Q-PAC's flow-through structure of thin grids and rods provides drip points that break streams of water into torrential rain of tiny droplets. These droplets fill three-dimensional space, with each presenting its entire surface area to the passing gas phase. The total surface area far exceeds that of conventional packings, while air flows through with minimal resistance. Turbulent gas flow further breaks liquid into smaller droplets, maximizing surface area per unit volume.

Higher Capacity & Flexible Equipment Sizing

Q-PAC operates at gas velocities exceeding 600 ft/min—roughly twice conventional packing velocities of 350 ft/min. This enables dramatic equipment downsizing: smaller tower diameters, reduced pumps, lower blower motors, and compact mist eliminators. One documented installation saved over $500,000 versus conventional packing designs.

For existing equipment, Q-PAC retrofits boost capacity at a fraction of new tower costs. Scrubbers switching to Q-PAC operate at higher velocities while achieving superior removal efficiencies.

Outstanding Fouling Resistance

Q-PAC's uniformly spaced bar-and-rod geometry and superior wetting capability promote self-cleaning by eliminating dry spots. This minimizes plugging from mineral scale or biological growth, reducing maintenance downtime and making Q-PAC ideal for scrubbers using reclaimed water.

Cost-Effective Solution

Q-PAC's low weight per cubic foot reduces material costs, particularly for specialty thermoplastics needed for heat and corrosion resistance. Combined with smaller equipment sizing and reduced operating costs, Q-PAC delivers exceptional value across the project lifecycle.

Key Benefits

-

30-50% Higher Capacity – Higher flow rates in existing towers, or smaller new towers

-

Lower Capital Costs – Smaller tower diameters, recirculation pumps, blower motors, mist eliminators, and less packing volume

-

Reduced Operating Costs – Lower fan power costs, less noise, reduced maintenance

-

Fouling & Plugging Resistant – Uniformly spaced bar-and-rod design with self-cleaning properties

-

Proven Worldwide – Thousands of successful installations across diverse applications

Performance Data & Literature

- Q-PAC Brochure in PDF Format

- Metric: Q-PAC® Pressure Drop Curves

- Metric: Q-PAC® Pressure Drop Comparisons

- 16-Page Q-PAC® Data.pdf (1750 kb)

- DataA: Designing with Q-PAC®

- DataB: Acid Gas Scrubbing

- DataC: Flooding Curve

- DataD: Pressure Drop

- DataE: Liquid Holdup

- DataF: Packing Comparisons

- DataH: HTU Curves

Technical Specifications

| Parameter | British Units | Metric Units |

|---|---|---|

| Dimensions | 3.25″ x 3.75″ | 8.25cm x 9.5cm |

| Void Fraction | 96.3% | 96.3% |

| Geometric Surface Area | 30 ft²/ft³ | 98.4 m²/m³ |

| Weight – polypropylene | 2.1 lb/ft³ | 33.7 kg/m³ |

| Weight – PVDF | 4.1 lb/ft³ | 65.8 kg/m³ |

| Number of Pieces | 33/ft³ | 1165/m³ |

| Packing Factor | 7/ft | 23/m |

| Number of Dripping Points | 11,000/ft³ | 388,000/m³ |

Note: Q-PAC® is available in a number of thermoplastics. Please call 617-302-3269 to inquire.

Resources

Downloads

-

{{DOWNLOADS_LIST}}

Related Products

-

{{RELATED_PRODUCTS_LIST}}